What is laser diode module?

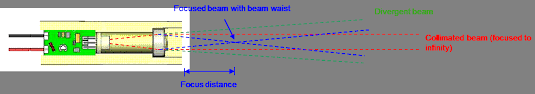

Laser diode modules are combing various wavelengths laser diodes, glass coated lens, electric driving circuit board with highly durable anodized aluminum alloy housing tube. Owing to perfect design of thermal emitting system and power source supply, it is always operating much easier than formal laser diodes. Most of them are used for industrial precise dot measurement, high tech fields etc. It projects high collimation laser beam, and highly clear laser dot onto various working surfaces.

Output power

Not the same as a simple laser diode made laser pointer, the genuine use of laser diode module is always continuing for quite long time and be used with various output power. Visible lasers get wide range output power of 5mW to 100mW, and invisible infrared lasers gets different output power of 5mW to 500mW.

For operation of long distance, high lighting and other complex working environment etc, high power laser modules are in need, thus OEM laser are being designed and manufacturing with high output power range of 200mW to 1000mW, applying for even longer distance and high lighting occasions etc.

Cooling system and beam stabilization:

No matter what output power it is using, laser diode module gets advanced use of metal heat sink cooling system inside high duration anodized aluminum alloy housing tube. It can facilitated the cooling, good thermal conductivity and wide operating temperature and storage temperature as well.

For high power laser modules, after special use of external configured metal heat sink part, it gets excellent thermal emitting, and high level of laser beam stability up to 85% within long lasting dot measurement within 8 to 10 hours constant work.

Temperature stabilization is important design for all output power made laser diode modules, since the junction temperature effects the emission wavelength seriously. Configured with thermoelectric cooler(TEC) with anodized aluminum alloying housing tube design, it makes excellent feedback of the most stable diode temperature, and leads to even more stable output power and output wavelength in long lasting use.

Power supply

Most of laser diode modules adopt AC/DC adapter, available with different operating voltage of 5V, 9V, 12V on basis of different output power. It enables larger space leaving for tube cooling down, and highly stable and reliable laser beam emission and laser dot alignment in long lasting use. It performs well without any effect by overheating and over current.

OEM lasers are being made with special designed battery power source, or pulsing laser on basis of real need.

APC driving circuit board

Whatever output power it is choosing, laser diode module with any output power or wavelength keeps work with constant output power and electric current supply. It gets perfect protection of itself under overheating and over current impact, reduced possibility of tube burning out or damage, and long serving lifetime of more than 8,000 hours.

Applications:

Application of 405nm to 1064nm laser diode modules are covering a large fields, including precise dot positioning and alignment of optical elements, drilling system, printing and imaging system, laser displaying, laser communications, optical data processing, laser medical therapy and surgery, military dot positioning work etc.

OEM lasers are also able to be used as accessory part of large scale device or equipment, integrated with larger devices of robots or others hand held laser devices etc.

Post Comments

You must be logged in to post a comment.

Click here to log in